- AI’s rapid growth highlights an urgent energy and environmental crisis due to increased electricity consumption in chip manufacturing.

- Chip production in countries like Taiwan, South Korea, and Japan surged electricity use by 350% last year, consuming 984 gigawatt hours.

- Carbon dioxide emissions from electricity generation quadrupled, totaling 453,600 metric tons in 2024, underscoring significant environmental costs.

- Projections indicate that AI chip manufacturing could exceed Ireland’s current electricity use by 2030.

- Tech giants—Nvidia, Microsoft, Meta, Google—are urged to prioritize sustainable practices and renewable energy sources by 2030.

- Efforts by companies like TSMC highlight challenges and slow progress in achieving low-carbon manufacturing.

- Transitioning to greener chip production is crucial for balancing technological advancement with environmental responsibility.

The relentless appetite for artificial intelligence is reshaping our world, promising smarter technology and increased efficiency. Yet, beneath this shiny veneer lies an energy crisis brewing in the shadows of global chip manufacturing. Through a lens of striking detail, the environmental implications of this digital revolution come into focus, revealing an urgent need for a greener path forward.

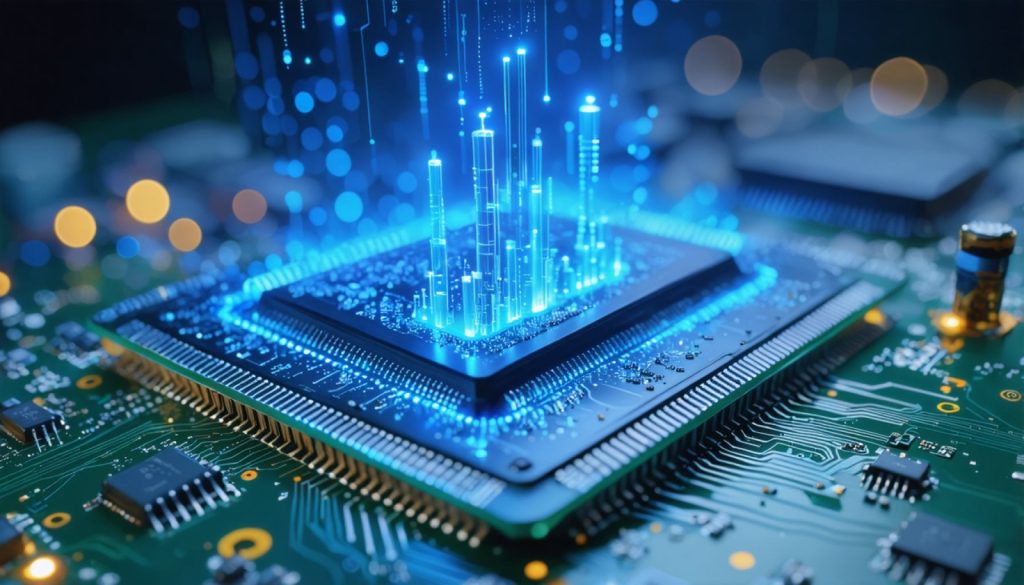

Visualize bustling factories in East Asia, where tiny silicon wafers are crafted into the sophisticated processors that will power tomorrow’s AI systems. These technological marvels, produced in hubs like Taiwan, South Korea, and Japan, quietly drive up electricity use. Each wafer requires vast amounts of energy, impressive in its demand, as the pursuit for AI advancement intensifies. The numbers tell a compelling story: chip manufacturing alone guzzled nearly 984 gigawatt hours of electricity last year—an astonishing leap of over 350 percent from the previous year.

The repercussions of such energy consumption ripple across the globe, as emissions from generating this electricity quadrupled in a single year. In 2024, approximately 453,600 metric tons of carbon dioxide filled the atmosphere, begging the question: at what environmental cost does technological advancement come?

A seamless dance of smoke billows from fossil fuels as they power these intricate operations, a stark reminder of the industry’s lingering reliance on non-renewable energy sources. The projection is even more staggering, with AI chip manufacturing predicted to consume more than the entire current electricity consumption of Ireland by 2030.

With tech giants like Nvidia, Microsoft, Meta, and Google steering this AI-driven voyage, the call for action resounds loudly. It is no longer enough to innovate; the commitment to environmental stewardship must walk in tandem. This means propelling suppliers towards a sustainable future, aiming for a supply chain powered entirely by renewable energy by the end of the decade.

Yet, challenges loom large. Major players like Taiwan Semiconductor Manufacturing Co (TSMC) have made strides toward low-carbon manufacturing but still face the slow churn of progress. The time for a synchronized energy revolution has arrived—a collective effort that refuses to leave sustainability in the realm of wishful thinking.

The promise of AI holds boundless potential, akin to a double-edged sword. As the world races forward in this digital age, let it not forget the responsibility of nurturing the planet that supports these leaps. The path to cleaner, greener chip manufacturing may seem formidable, but it is a journey that technology leaders must embrace with urgency and tenacity.

By inspiring a shift toward renewable energy, technology not only provides solutions but breathes hope into our shared future, where innovation and environmental harmony coexist.

Unmasking AI’s Hidden Cost: Energy Consumption in Chip Manufacturing

Introduction

The relentless pursuit of artificial intelligence advancements is reshaping our world, promising smarter technology and increased efficiency. However, amidst this technological renaissance lies a brewing energy crisis primarily driven by global chip manufacturing. This article dives deep into the environmental implications of the digital revolution, spotlighting the urgent need for more sustainable practices.

The Energy-Hungry Reality of Chip Manufacturing

Picture bustling factories across East Asia—in countries like Taiwan, South Korea, and Japan—where advanced processors for AI systems are crafted. While these technological marvels enable the cutting-edge world of AI, they come at a steep energy cost.

Each tiny silicon wafer, a critical component of AI chips, demands immense electricity for production. The consumption statistics are staggering: chip manufacturing consumed nearly 984 gigawatt-hours of electricity last year, reflecting a 350% increase from the previous year. The environmental repercussions are profound, with carbon emissions from this electricity generation quadrupling, adding nearly 453,600 metric tons of CO2 to the atmosphere in 2024 alone.

The Path Forward: Embracing Renewable Energy

Challenges and Opportunities:

With technology leaders like Nvidia, Microsoft, Meta, and Google at the helm of the AI movement, the impetus for sustainable solutions is vital. Shifting towards a supply chain entirely powered by renewable energy by the decade’s end is critical. Although companies like Taiwan Semiconductor Manufacturing Co (TSMC) have made progress towards low-carbon manufacturing, the rate of progress must accelerate.

The prediction that AI chip manufacturing could consume more electricity than entire countries underscores the need for comprehensive, immediate action.

Real-World Use Cases and Emerging Trends

AI-powered devices and applications bring various benefits to industries, from healthcare to autonomous driving, heralding operational efficiency and innovation. However, without sustainable production and energy strategies, these advancements pose significant environmental challenges.

Trends Toward Greener Solutions:

1. Investment in Renewable Energy: Tech giants are increasingly investing in renewable energy projects. For instance, Google’s commitment to running its data centers on carbon-free energy by 2030 is a benchmark goal that others could emulate.

2. Innovative Cooling Solutions: Improving data center efficiency through advanced cooling technologies can significantly reduce energy consumption, making the processing of AI models less environmentally taxing.

3. Efficient Chip Architectures: Developing chips that use less power while maintaining performance is an ongoing priority in the field.

Recommendations for a Sustainable Future

1. Adopt Renewable Sources: Encourage and invest in solar, wind, and other renewable energy projects dedicated to powering manufacturing operations.

2. Optimize Chip Design: Prioritize research into energy-efficient chip designs to reduce the overall power needed for AI processes.

3. Policy and Incentives: Governments should establish policies and incentives to support industries shifting toward sustainable practices and renewable energy adoption.

4. Collaborative Efforts: Foster industry collaborations to share best practices and technologies for environmentally friendly manufacturing.

Conclusion: Immediate Actions for Sustainable AI Growth

The promise of AI is monumental, demanding a balance between technological advancement and environmental impact. By aligning innovation with sustainability goals, companies can pave a greener path forward. Embracing renewable energy and energy-efficient practices will ensure that AI’s potential doesn’t come at the Earth’s expense.

For further insights and detailed strategies, visit IEEE or follow Nature to stay updated on advancements in sustainable technology solutions.