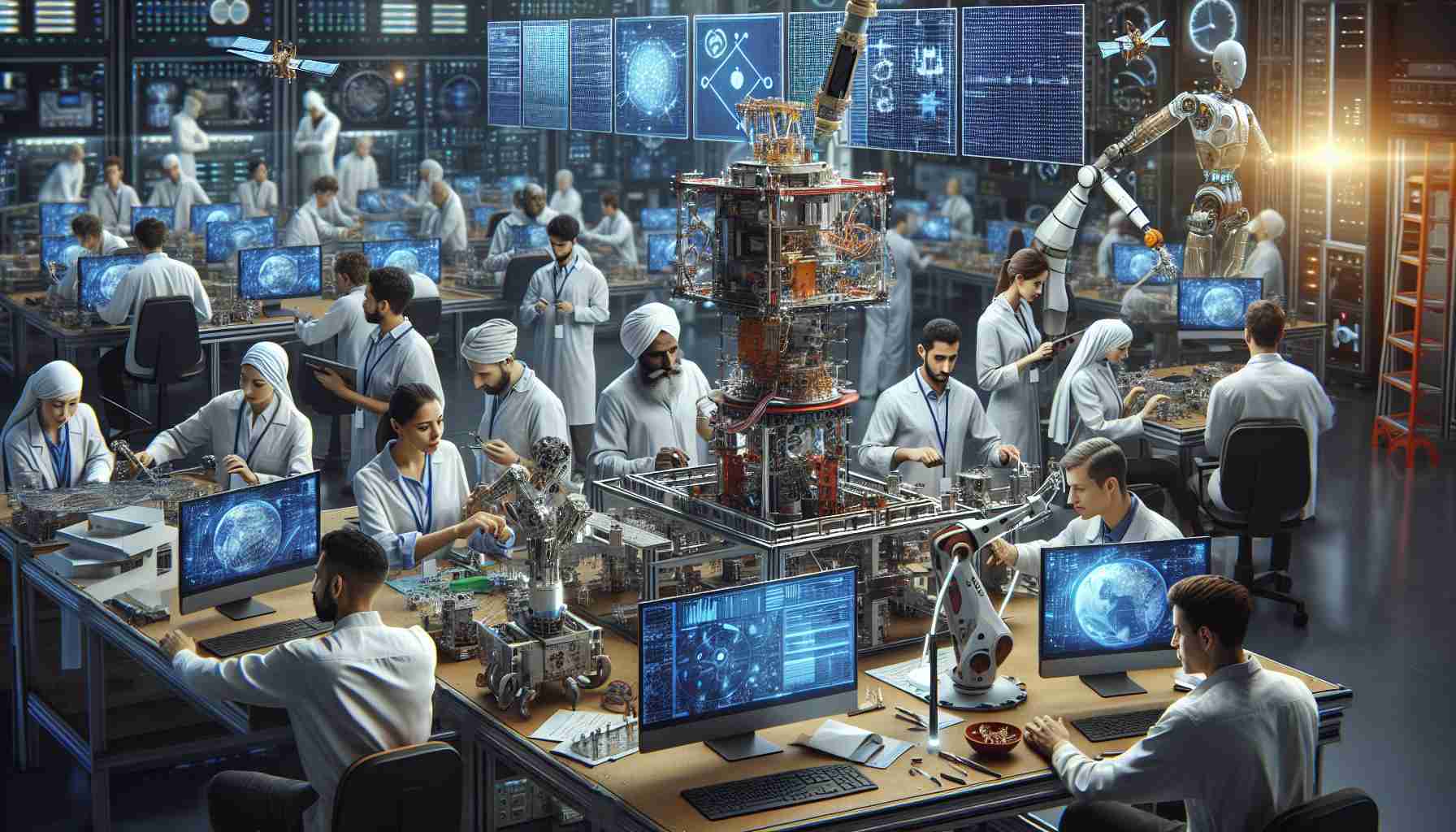

MOUNTAIN VIEW, Calif. – The integration of artificial intelligence (AI) into satellite manufacturing is advancing, though companies are approaching it with caution. For instance, Blue Canyon Technologies is exploring how AI can enhance manufacturing processes while emphasizing the importance of cybersecurity.

Concerns about data management are paramount. The general manager of Blue Canyon Technologies highlighted the critical issue of data security when teaching AI systems, questioning the origins and pathways of this data. Despite these challenges, AI shows potential in refining the engineering design phase, enabling teams to convert extensive datasets into actionable insights.

In a similar vein, Kongsberg NanoAvionics has echoed concerns over the reliability of AI outputs. The engineering operations director expressed uncertainty about the trustworthiness of AI-derived results, stressing the need for transparency regarding data sources. This wariness hinders immediate integration of AI in manufacturing and testing until these uncertainties are resolved.

In contrast, Machina Labs, a startup from Los Angeles, is making strides by generating its own reliable data. Their approach relies on advanced robotics that collect and analyze manufacturing data independently. This allows them to assess whether produced parts meet specific requirements through an accurate monitoring system.

The company’s vice president mentioned that they are only beginning to tap into the potential of this self-generated data to optimize their processes and minimize defects in future productions.

The Cautious Adoption of AI in Satellite Production: A Deep Dive into the Future of Space Technology

As the aerospace industry heads into an era defined by high-tech innovations, the cautious adoption of artificial intelligence (AI) in satellite production is unfolding. Companies are keen to integrate AI’s capabilities to streamline processes and boost productivity but are equally wary of potential pitfalls. Several factors influence this careful approach, including technical risk management, regulatory compliance, and ethical considerations.

What are the primary benefits of integrating AI into satellite production?

AI applications in satellite manufacturing can lead to several advantages:

– Efficiency Gains: AI can automate repetitive tasks, thereby speeding up production cycles and reducing labor costs.

– Enhanced Design Capabilities: Machine learning algorithms can process vast data sets to optimize satellite designs for performance and reliability.

– Predictive Maintenance: AI can analyze data from sensors embedded in satellites to predict potential system failures, enabling proactive maintenance and reducing downtime.

What are the challenges and controversies surrounding AI in this sector?

Despite the advantages, several challenges must be addressed:

– Data Security Concerns: As highlighted by leaders in the industry, the ethical management and security of data used to train AI systems is a significant concern. Ensuring that proprietary or sensitive information is safeguarded remains paramount.

– Regulatory Hurdles: The aerospace industry is heavily regulated, and the introduction of AI technologies raises questions about compliance with existing laws and standards.

– Trust in AI Systems: The reliability of AI outputs is not guaranteed. Many experts express skepticism about whether AI can produce results that are as dependable as traditional engineering practices.

What is being done to mitigate these challenges?

Companies like Blue Canyon Technologies and Kongsberg NanoAvionics are imposing stringent protocols to deal with data management issues. They are advocating for robust frameworks ensuring transparency and traceability in data sources. Additionally, partnerships with academic institutions and technology firms are becoming common to develop stronger AI systems that comply with safety guidelines and ethical standards.

Is there a divide in AI adoption among different sized companies?

Indeed, larger companies may have more resources to invest in AI technology, including specialized teams and advanced infrastructure. However, smaller firms like Machina Labs are also innovating rapidly by creating autonomous data systems that allow for effective AI integration without substantial resource investments.

What are the potential drawbacks of AI in satellite production?

The potential disadvantages include:

– High Initial Costs: Integrating AI technologies requires significant upfront investments.

– Job Displacement: Increased automation might lead to concerns around job losses in certain roles within the satellite production process.

– Over-reliance on Technology: There is a risk that critical thinking could diminish as teams become more dependent on AI-generated outputs.

As the industry progresses, companies will undoubtedly continue to navigate these complexities to find a balanced approach to AI adoption in satellite manufacturing. The journey towards an AI-optimized satellite production landscape is filled with potential but requires diligent effort and commitment to overcome the inherent challenges.

For more information on AI advancements in aerospace, visit aerospace.org for a comprehensive view of the aerospace industry’s technological developments.