- Thousands gathered in San Jose, California, for Nvidia’s annual developer conference, highlighting innovations in humanoid robotics.

- Nvidia CEO Jensen Huang unveiled software tools to enable robots to navigate complex industrial environments with cognition.

- The manufacturing sector is expected to adopt humanoid robots first, leveraging their precision in structured workflows.

- The estimated cost of a humanoid robot is $100,000, deemed a smart investment for increased efficiency and output.

- Humanoid robots will handle routine tasks, allowing human workers to focus on more complex challenges.

- This technological shift addresses labor shortages and enhances productivity, marking a strategic evolution in industries.

- The integration of robotics with human workers aims to achieve harmonious collaboration, boosting creativity and efficiency.

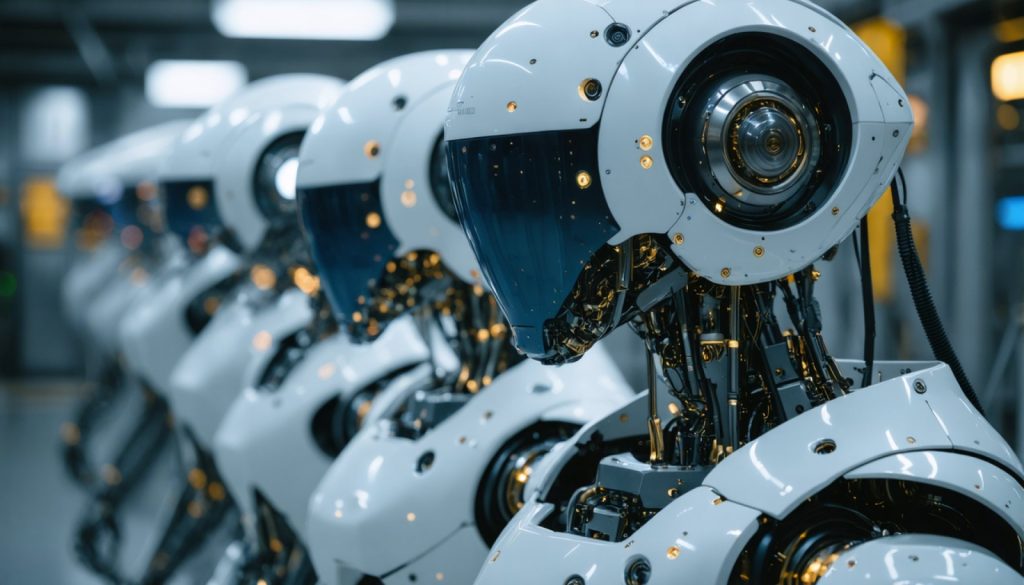

The ambient hum of excitement filled the air as thousands flocked to San Jose, California, gripped by an electrifying energy that could only be sparked by the cutting-edge advancements in technology. Amidst this charged atmosphere, Nvidia CEO Jensen Huang addressed an eager crowd during the tech giant’s annual developer conference, painting a vivid picture of the future—a future where humanoid robots roam factory floors.

Jensen Huang stood at the epicenter of the tech universe, unveiling software tools designed to grant robots the cognition needed to navigate the complexities of our world. It wasn’t just innovation for innovation’s sake. His vision was clear: humanoid robots are not just distant specters of science fiction but imminent realities, poised to redefine industrial landscapes within a mere handful of years.

With a profound conviction, Huang articulated that the manufacturing sector is primed to adopt these mechanical beings first. Manufacturing, with its regimented and repetitive workflows, provides a structured environment that suits the precision and predictability of robotics. The notion of robots integrated alongside human counterparts conjures vivid imagery of a harmonious blend of machinery and humanity, each playing to its strengths in a symphony of productivity.

Huang emphasized that this transition is not only transformative but economically viable. He posited that the cost of deploying a humanoid robot—estimated at around $100,000—represents a sound investment when considering the potential gains in efficiency and output. These robots would undertake well-defined tasks, leaving human workers to tackle more intricate and dynamic challenges.

As businesses stare down the challenges of labor shortages and seek ingenious ways to elevate their operations, this robotic revolution promises a compelling remedy. The integration of humanoid robots into factories is more than just a technological milestone—it is a strategic evolution that promises to propel industries toward unprecedented heights of efficiency and creativity.

Amidst the advancing waves of artificial intelligence and robotics, the key takeaway resonates with clarity: Embracing this technology not only prepares industries for a more automated future but also unlocks new avenues for human ingenuity to thrive.

As the dust settles from the conference, the implications of Huang’s forecast continue to ripple outward. The horizon is marked by silhouettes of machines with human-like grace, and the countdown to their debut has already begun. Each stride they take will be a stride toward reimagining the very fabric of industrial operations, ushering in a new era where man and machine work hand in hand, not in competition, but in collaboration.

The Robot Revolution: Transforming Factories with Human-Like Precision

Introduction

The tech community is abuzz after Nvidia’s annual developer conference in San Jose, California, where CEO Jensen Huang unveiled groundbreaking software tools designed to fundamentally reshape the industrial landscape. Huang’s vision is clear: humanoid robots are poised to enter factories, revolutionizing manufacturing processes by working hand-in-hand with human counterparts. Let’s dive deeper into the implications of this technological shift, explore real-world use cases, and understand what this means for the future of industries worldwide.

Real-World Use Cases and Industry Trends

1. Manufacturing Revolution: As Huang highlighted, the most imminent application for humanoid robots is within the manufacturing sector. The repetitive and predictable nature of factory work makes it an ideal starting point. Robots could manage routine tasks such as assembly line work, quality control, and inventory management, freeing human workers to focus on complex problem-solving and innovation.

2. Logistics and Warehousing: Beyond manufacturing, humanoid robots are poised to transform logistics. By improving efficiency in warehouses with tasks like sorting, packing, and even navigating complex layouts, robots can significantly reduce costs and improve delivery times.

3. Healthcare Assistance: Although initially focused on industrial applications, the adaptability of humanoid robots holds promise for healthcare. Robots can assist in surgeries, patient monitoring, and elder care, alleviating the strain on healthcare professionals.

Pressing Questions and Answers

How does the cost of deploying humanoid robots compare to human labor?

The initial investment in humanoid robots, approximately $100,000 each, may appear daunting; however, the return on investment is compelling. Robots can operate 24/7 without fatigue, significantly boosting productivity, reducing error rates, and minimizing downtime. Over time, these efficiencies translate to substantial cost savings compared to traditional human labor.

Are there any ethical considerations with the deployment of humanoid robots?

Yes, there are several ethical considerations, including job displacement, data privacy, and the need for transparent AI algorithms to ensure fair decision-making. Businesses must prioritize ethical guidelines and proper training to ensure a smooth transition.

Security and Sustainability Considerations

1. Data Protection: The integration of robotics and AI involves massive amounts of data. Companies must implement robust cybersecurity measures to protect sensitive information and maintain operational integrity.

2. Environmental Impact: Manufacturers should prioritize sustainable practices by using energy-efficient robotics and materials, thus aligning with global ethical standards for sustainability.

Pros and Cons Overview

Pros:

– Increased Efficiency: Automation reduces human error and enhances production speed.

– 24/7 Operation: Unlike human workers, robots can work continuously, increasing productivity.

– Reduces Labor Costs: Over time, savings in labor costs and increased output balance the initial investment.

Cons:

– High Initial Costs: Significant upfront investment may be prohibitive for smaller businesses.

– Job Displacement: Potential loss of jobs for workers in routine roles necessitates retraining programs.

– Technical Dependence: Increased reliance on technology may lead to vulnerabilities if systems fail.

Actionable Recommendations

– Invest in Retraining: Businesses should invest in employee retraining programs to equip workers with skills for higher-value tasks.

– Start Small: Implement robots in a phased manner to allow ample time for adjustment.

– Focus on Cybersecurity: Establish strong cybersecurity measures from the start to protect data integrity.

Conclusion

The arrival of humanoid robots in industrial settings is not just a technological marvel but a strategic evolution poised to redefine efficiency and creativity in workflows. Emphasizing a collaborative synergy between human ingenuity and robotic precision, industries must proactively embrace these changes to stay competitive.

For further insight into cutting-edge technology and its impact on various sectors, visit Nvidia’s website to learn more about their latest innovations.